Redi-Rock

Redi-Rock

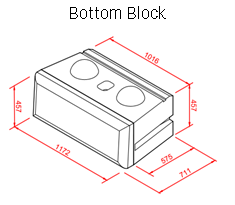

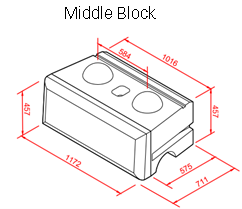

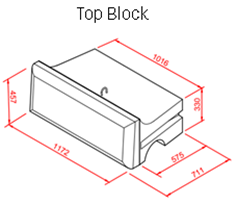

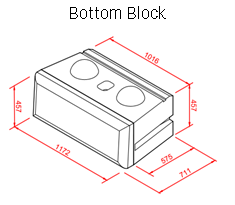

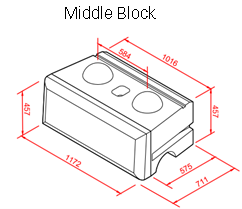

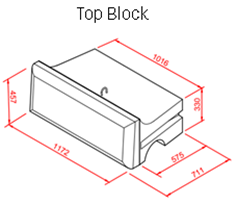

Redi-Rock retaining and freestanding walls can be rapidly constructed using the innovative 1 ton interlocking blocks. The precast concrete blocks are created in moulds and have a natural affect cobblestone finish. Redi-Rock is an engineered, interlocking concrete block which is capable of creating an instant retaining wall system that is versatile enough to achieve high structures without compromising strength. Creating Redi-Rock walls requires a combination of 3 different block types; Top, Middle & Bottom.

Precast Retaining Wall

In residential and commercial building projects, they can be used to manage changes in ground levels, and are particularly effective when time, access and cost constraints preclude the use of more labour-intensive solutions, such as gabion walls.

Precast Retaining walls are extremely durable because they have no potential damage points. Our products are constructed to resist any damage from constant weight-bearing, therefore, you can be reassured to receive the highest of quality.

For further information regarding Redi-Rock Please contact a member of our civil Sales Team on 028 2565 2566, Ext 3

Download BrochurePlease fill in your details to download brochure

-

Features & Specifications

Moore Concrete manufacture under license from Redi-Rock International of USA, creating benefits from a global business continuously investing in Research and Development to drive innovation, including sophisticated wall analysis software.

BBA approved. Roads and Bridges Agreement Certificate 12/R149

Blocks are manufactured in a factory controlled environment using durable wet cast high strength concrete to ensure durability, 100 year design life.

Designed in accordance with BS EN 1997-1:2004

Fully engineered design plan available for different heights and ground conditions, supported by professional indemnity insurance.

Cost efficient complete project solution.

Reduced site cost and risk, from reduced number of people and time required on site.

(Up to 60 blocks per 2 man team installation per day.)The precast modular blocks are ideal for quick and efficient installation – up to 10 times faster than traditional walls

Construction can occur in all weather conditions without the need for formwork, shuttering or mortar.

Flexible if plans change can easily pick up and build in another location.

Attractive natural stone finish.

Engineered strength, achieving height without Geogrid.

Space saving design. Geogrid is rarely needed.

Blocks have consistent dimensions making them easy to build with, providing a consistency of finish and which once installed preferable to walk or sit on.

Freestanding blocks have the option of face texture on 2 or 3 sides for projects where the back or side of the block is visible.

Very versatile with the ability to create curves and corners.

Redi-Rock products can all be used in-conjunction with each other to provide a consistent finish in project requiring retaining walls, freestanding walls, landscaping products.

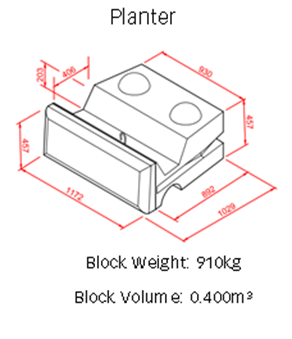

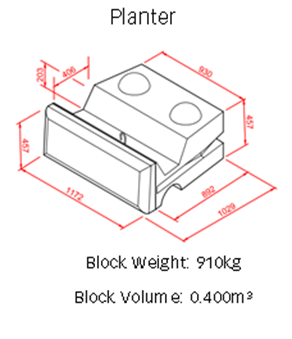

Freestanding walls can be topped with planter blocks or heavy capstones

Accessories like columns, steps, and caps coordinate perfectly with Redi-Rock retaining and freestanding walls to create an exceptional finish.

Minimum maintenance.

Redi-Rock’s Force Protection System is the most innovative perimeter protection product on the market. Post-Tension Cable and J-Bolt System: to link the blocks together.

Redi-Rock’s force protection system has been engineered and tested extensively. The post-tension cables running throughout the wall will allow it to flex when impacted. This flexibility gives the wall massive stopping power, with friction absorbing the kinetic energy of, for example, an impacting vehicle.

Blocks can be reinforced with cable to provide traffic control and force protection.

-

Product Dimensions

Redi-Rock Dimensions

We manufacture a range of Precast Retaining Walls. More details can be found below.

Moore Concrete are Redi-Rock International’s manufacturing and sales partner throughout the island of Ireland.

Moore Concrete can offer our customer advice and design services with the full backup of the experience and expertise including;

• Preliminary Design

• Full design / TAS Approval

• Installation Guide & Manual

XL Block

The XL Block has double the face height meaning half the installation time. It has a hollow core with a lighter weight, which lowers the cost of shipping. The XL blocks interlock with all existing blocks in the Redi-Rock system, providing more tools to build the most efficient retaining wall solution.Key Features:

– Double height face – 914mm (36”) Three widths available 1.37m (54”), 1.83m (72”) and 2.44m (96”).

– Taller gravity walls can be designed up to 6 meters without any geogrid.

-

Delivery

Moore Concrete will deliver your products to site.

For further information regarding Redi-Rock please contact a member of our Civils sales team on 028 2565 2566, Ext 3

We deliver throughout the UK and Ireland.

-

Projects

Roads- simple fast construction, minimises disruption to keep the traffic flowing.

Railways – space saving engineered solution prefect for railways.

Water for Coastal and Flood Plain Defence, Shoreline and Sea Defence– can be reinforced to withstand incredible storms.

Bridges – you can design a solution using Redi-Rock whether you need abutments, wing walls or retaining walls leading up to or supporting your bridge.

Housing and Commercial Developments – the versatility and ease of installation ensures a flexible retaining wall solution to maximise usable land, and create a beautiful aesthetic effect for the overall development.

Landscaping and Security

Protection Barriers

Seat Walls

Staircases

Columns

Landscape Design – for more information on please click Redi-Rock Landscaping

Moore Concrete manufacture under license from Redi-Rock International of USA, creating benefits from a global business continuously investing in Research and Development to drive innovation, including sophisticated wall analysis software.

BBA approved. Roads and Bridges Agreement Certificate 12/R149

Blocks are manufactured in a factory controlled environment using durable wet cast high strength concrete to ensure durability, 100 year design life.

Designed in accordance with BS EN 1997-1:2004

Fully engineered design plan available for different heights and ground conditions, supported by professional indemnity insurance.

Cost efficient complete project solution.

Reduced site cost and risk, from reduced number of people and time required on site.

(Up to 60 blocks per 2 man team installation per day.)The precast modular blocks are ideal for quick and efficient installation – up to 10 times faster than traditional walls

Construction can occur in all weather conditions without the need for formwork, shuttering or mortar.

Flexible if plans change can easily pick up and build in another location.

Attractive natural stone finish.

Engineered strength, achieving height without Geogrid.

Space saving design. Geogrid is rarely needed.

Blocks have consistent dimensions making them easy to build with, providing a consistency of finish and which once installed preferable to walk or sit on.

Freestanding blocks have the option of face texture on 2 or 3 sides for projects where the back or side of the block is visible.

Very versatile with the ability to create curves and corners.

Redi-Rock products can all be used in-conjunction with each other to provide a consistent finish in project requiring retaining walls, freestanding walls, landscaping products.

Freestanding walls can be topped with planter blocks or heavy capstones

Accessories like columns, steps, and caps coordinate perfectly with Redi-Rock retaining and freestanding walls to create an exceptional finish.

Minimum maintenance.

Redi-Rock’s Force Protection System is the most innovative perimeter protection product on the market. Post-Tension Cable and J-Bolt System: to link the blocks together.

Redi-Rock’s force protection system has been engineered and tested extensively. The post-tension cables running throughout the wall will allow it to flex when impacted. This flexibility gives the wall massive stopping power, with friction absorbing the kinetic energy of, for example, an impacting vehicle.

Blocks can be reinforced with cable to provide traffic control and force protection.

Redi-Rock Dimensions

We manufacture a range of Precast Retaining Walls. More details can be found below.

Moore Concrete are Redi-Rock International’s manufacturing and sales partner throughout the island of Ireland.

Moore Concrete can offer our customer advice and design services with the full backup of the experience and expertise including;

• Preliminary Design

• Full design / TAS Approval

• Installation Guide & Manual

XL Block

The XL Block has double the face height meaning half the installation time. It has a hollow core with a lighter weight, which lowers the cost of shipping. The XL blocks interlock with all existing blocks in the Redi-Rock system, providing more tools to build the most efficient retaining wall solution.

Key Features:

– Double height face – 914mm (36”) Three widths available 1.37m (54”), 1.83m (72”) and 2.44m (96”).

– Taller gravity walls can be designed up to 6 meters without any geogrid.

Moore Concrete will deliver your products to site.

For further information regarding Redi-Rock please contact a member of our Civils sales team on 028 2565 2566, Ext 3

We deliver throughout the UK and Ireland.

Roads- simple fast construction, minimises disruption to keep the traffic flowing.

Railways – space saving engineered solution prefect for railways.

Water for Coastal and Flood Plain Defence, Shoreline and Sea Defence– can be reinforced to withstand incredible storms.

Bridges – you can design a solution using Redi-Rock whether you need abutments, wing walls or retaining walls leading up to or supporting your bridge.

Housing and Commercial Developments – the versatility and ease of installation ensures a flexible retaining wall solution to maximise usable land, and create a beautiful aesthetic effect for the overall development.

Landscaping and Security

Protection Barriers

Seat Walls

Staircases

Columns

Landscape Design – for more information on please click Redi-Rock Landscaping