Above Ground Slurry Store

Above Ground Concrete Slurry Store

Our Above Ground Concrete Slurry Stores ensure the optimum combination of economy, reliability and durability, and fully meet requirements outlined under both the Irish and British specifications for farm waste management.

Moore Concrete’s Slurry Stores are also approved under the Targeted Agricultural Modernisation Scheme (TAMS III) in the Republic of Ireland.

TAMS III Minimum Specification Details

Concrete Storage Tanks

Our concrete slurry store tanks are designed and constructed in full compliance with British and European Design Codes, the Above Ground Slurry Store offers the farmer proven Danish Technology. This tried and tested system has been in use for over 30 years.

For further information regarding Above Ground Slurry Store Please contact a member of our agriculture Sales Team on 028 2565 2566, Ext 1

Make an Enquiry-

Features & Specifications

Moore Concrete offer a complete service – supply & construction of materials for both the base & store. Every store is inspected by a Chartered Engineer both pre & post construction.

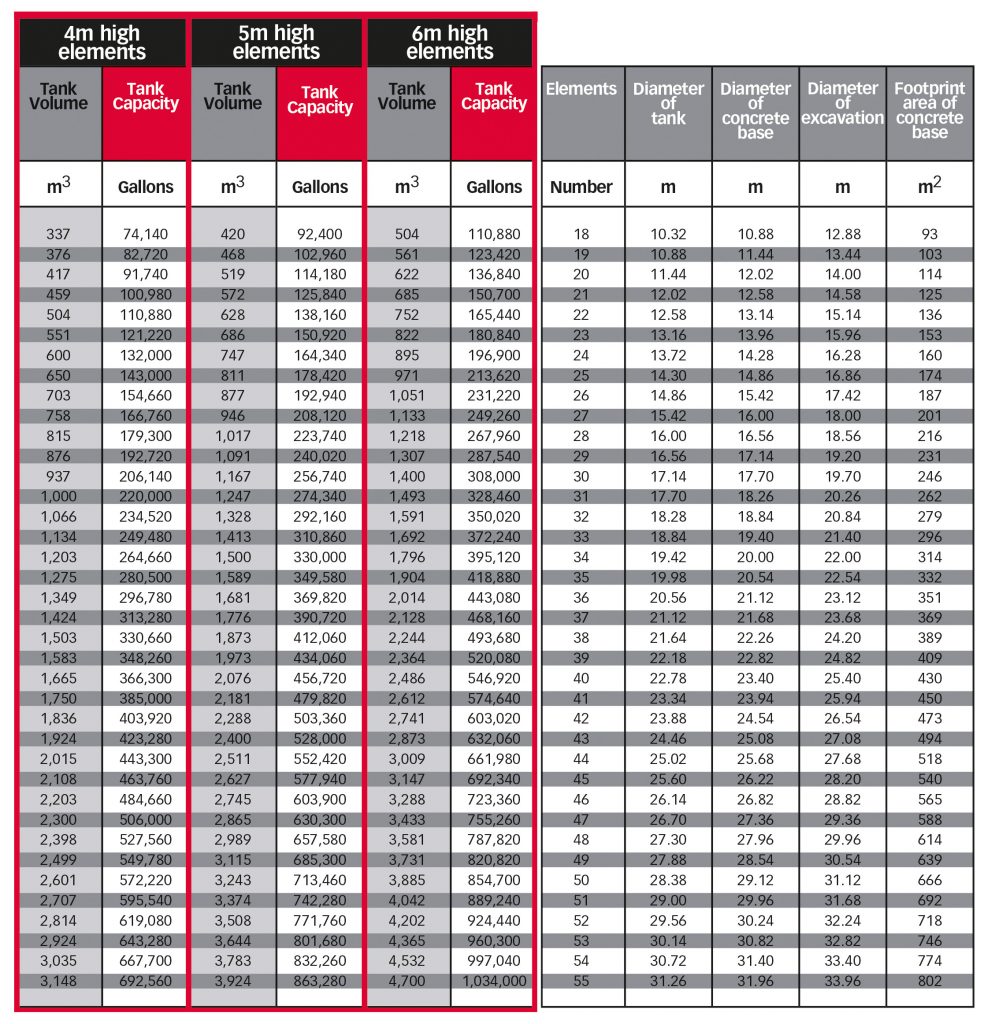

Slurry storage tanks are available in 3 heights – 4.0, 5.0m & 6.0m giving a wide range of capacities – 337m3 (74,140 Gallon) – 4700m3 (1,034,000 Gallon).

Post Tensioned Cables are encased in a PVC sheath to protect them for the lifetime of the store without maintenance.

Rapid installation – just 7 days on site (total project length approximately 1 month subject to size of store & weather). See more in Delivery & Install.

Proven Danish Technology which has been in use for over 30 years.

Concrete slurry tanks can be partially or fully submerged into the ground, subject to consultation & design by a Chartered Engineer.

Precast concrete store elements are manufactured in controlled factory conditions to ISO 9001.

Complies with BS 5502-50 Code of practice for design, construction and use of storage tanks and reception pits.

Compliant with Nitrate Vulnerable Zones (NVZ) & Storing silage, Slurry and Agricultural fuel oil (SSAFO) regulations.

Inlet & outlets can be cast into Store Elements to facilitate pipes, mixers & drawoffs.

Flexibility to allow retro fitting of a Soft Cover at a later date if required.

Moore Concrete can provide optional ancillary equipment within a bespoke package for your particular requirements including:

Platform, Ladder & Jetter

Reception Tank

Side Stirrer

150mm Underwall or Through the Wall Draw off, including x2 150mm Valves

Soft Cover

-

Delivery & Install

Above Ground Concrete Slurry Store Installation & Delivery

Moore Concrete offer a complete service – supply & construction of materials for both the base & store. Every store is inspected by a Chartered Engineer both pre & post construction.

Construction Timeline

Day 1 on site – set up base for store

Day 2 on site – pour concrete base for the store

Curing period of 7 days for the concrete base

Day 3 & 4 on site – placement of vertical wall panels, placement of Post Tensioning Cables & Initial Stressing

Day 5 & 6 on site – Sealing Vertical Joints with expansive Mortar. Pouring Ring Beam. 7 Day Curing Period for Concrete Beam

Day 7 on site – Final Stressing of Post Tensioning Cables

Soft Tank Cover can be ordered on request.

Lundsby Soft Cover is a tried & tested patented product which has been installed to tanks throughout Europe. The covers ensure a durable & effective seal for the tank, keeping out rainwater and therefore increasing slurry capacity. The cover can be installed either at the erection of the new tank or retro fitted at a later date.

Whilst in many regions a cover is an option, in Northern Ireland it is a legal requirement.

Moore Concrete offer a complete service – supply & construction of materials for both the base & store. Every store is inspected by a Chartered Engineer both pre & post construction.

Slurry storage tanks are available in 3 heights – 4.0, 5.0m & 6.0m giving a wide range of capacities – 337m3 (74,140 Gallon) – 4700m3 (1,034,000 Gallon).

Post Tensioned Cables are encased in a PVC sheath to protect them for the lifetime of the store without maintenance.

Rapid installation – just 7 days on site (total project length approximately 1 month subject to size of store & weather). See more in Delivery & Install.

Proven Danish Technology which has been in use for over 30 years.

Concrete slurry tanks can be partially or fully submerged into the ground, subject to consultation & design by a Chartered Engineer.

Precast concrete store elements are manufactured in controlled factory conditions to ISO 9001.

Complies with BS 5502-50 Code of practice for design, construction and use of storage tanks and reception pits.

Compliant with Nitrate Vulnerable Zones (NVZ) & Storing silage, Slurry and Agricultural fuel oil (SSAFO) regulations.

Inlet & outlets can be cast into Store Elements to facilitate pipes, mixers & drawoffs.

Flexibility to allow retro fitting of a Soft Cover at a later date if required.

Moore Concrete can provide optional ancillary equipment within a bespoke package for your particular requirements including:

Platform, Ladder & Jetter

Reception Tank

Side Stirrer

150mm Underwall or Through the Wall Draw off, including x2 150mm Valves

Soft Cover

Above Ground Concrete Slurry Store Installation & Delivery

Moore Concrete offer a complete service – supply & construction of materials for both the base & store. Every store is inspected by a Chartered Engineer both pre & post construction.

Construction Timeline

Day 1 on site – set up base for store

Day 2 on site – pour concrete base for the store

Curing period of 7 days for the concrete base

Day 3 & 4 on site – placement of vertical wall panels, placement of Post Tensioning Cables & Initial Stressing

Day 5 & 6 on site – Sealing Vertical Joints with expansive Mortar. Pouring Ring Beam. 7 Day Curing Period for Concrete Beam

Day 7 on site – Final Stressing of Post Tensioning Cables

Soft Tank Cover can be ordered on request.

Lundsby Soft Cover is a tried & tested patented product which has been installed to tanks throughout Europe. The covers ensure a durable & effective seal for the tank, keeping out rainwater and therefore increasing slurry capacity. The cover can be installed either at the erection of the new tank or retro fitted at a later date.

Whilst in many regions a cover is an option, in Northern Ireland it is a legal requirement.